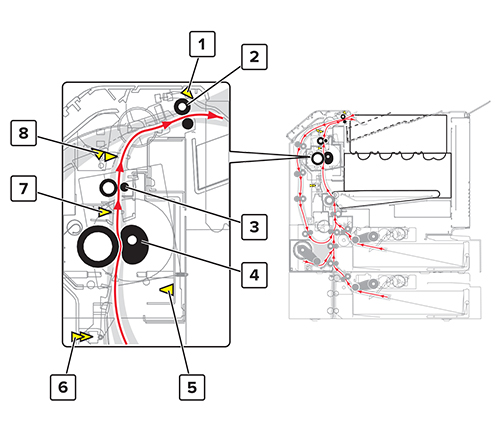

After the second transfer, the paper is fed to the fuser. The paper passes through the sensor (fuser buckle) located before the fuser. The sensor detects the buckle in the paper when it hits the fuser rollers. If the buckle is too great, the motor (fuser) speeds up to avoid causing a paper jam. If the buckle is too small, the motor slows to avoid smearing the image. The sensor (fuser nip) detects if the rollers are holding the paper. At the same location, the sensor (narrow media) is also present. The sensor (narrow media) detects whether narrow paper is being passed through. Depending on the width of the paper detected, a process speed change, fuser temperature change, and print speed change occurs to avoid damaging the fuser. The paper then passes through the fuser where heat and pressure are applied to melt the toner particles and bond them permanently to the paper. As the paper leaves the fuser, the paper passes through the sensor (fuser exit). The sensor (fuser exit) detects fuser wraps and helps prevent wraps to go completely around the belt. The paper then moves through the decurl rollers and passes through the sensor (paper exit). If the print job is one-sided, the paper is passed through the exit rollers and into the output bin. If the print job is duplex, the paper is retracted into the duplex path after the trailing edge passes through the sensor (paper exit) actuator.

| # | Description |

|---|

1 | Sensor (bin full) |

2 | Exit roller |

3 | Decurl roller |

4 | Fuser |

5 | Sensor (fuser nip) |

6 | Sensor (fuser buckle) / Sensor (narrow media) |

7 | Sensor (fuser exit) |

8 | Sensor (paper exit) / Sensor (duplex entry) |